It is sometimes required to deal with different physical phenomena origins to describe complex problems: thermal, mechanical, hydral, chemical, thermo-metallurgical, electrical…

Thermomechanical Simulation:

Aurock can provide various thermomechanical simulations, for example:

- Guidance on design of parts subjected to thermomechanical stresses

- Evaluation of thermal distortion (contraction, warping) caused by uneven heating and cooling after the extraction from the furnace

- Damage modelling of tools under thermomechanical cycles caused by a forming process

- Thermomechanical behavior of substrates under thermal spraying

- …

Some examples of multiphysics modeling

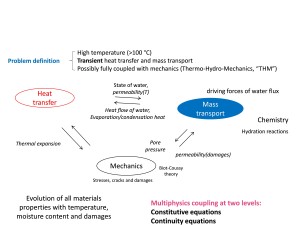

- – Thermohydral simulation of drying:

Drying of refractory castables is a process consisting of water removal after manufacturing through a temperature increase. The typical phenomena dread is the spalling due to the rapid increase of internal pressure of vapor. The system to consider is a non-equilibrium opened one with coupling between heat transfer, mass transfer in porous media (gas and liquid) and mechanical behavior. The approach helps to choose the time-saving heating cycle that preserves the mechanical integrity.

Thermo-Hydro-Mechanical (THM) coupling during drying of refractories